Piping

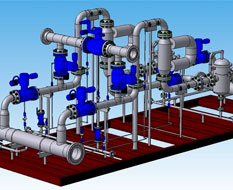

Conceptual Plot Plan for the project starts with the piping design activities. Layout of equipment items, interconnecting pipe racks, tanks and utility piping. The facility layout is designed under multi-discipline engineering review to consider the safety and operational aspects of the plant. In piping engineering we undertake the following activities:

Conceptual Plot Plan for the project starts with the piping design activities. Layout of equipment items, interconnecting pipe racks, tanks and utility piping. The facility layout is designed under multi-discipline engineering review to consider the safety and operational aspects of the plant. In piping engineering we undertake the following activities:

- Preliminary Plot Plans and Layouts

- Equipment Layouts

- Piping General Arrangement Drawings

- Piping Material Specifications

- Optimum Pipe Diameter

- Pipe Class Material of Construction Thickness / Schedule Number

- Pipe Stress Analysis

- Piping Isometrics

- Pipe Insulation Material Thickness

- Pipe Support and hanger Calculations

- Pipe Support Details.

- Pipe support modelling

- Special support design

- Preparation material take off list for piping, valves, pipe fitting, insulation etc.

- Pipe rack and pipe Trenches

- Valve data sheet

- Tie - In Schedules

- Tracing / jacketing

Our engineers have expertise in related activities such as review of design criteria, review of contractor design documents and project co-ordination.

They are experienced in the use of a variety of supporting software including PDS, PDMS, SmartPlant 3D, AutoPlant 3D, AutoCAD, MicroStation, Smart Plant Review, NavisWorks and CAESAR II